BRL has obtained a portfolio of patents that cover the entire technology, with protection extended worldwide, accrediting novelty and inventiveness in all its applications, laying the foundations to offer an ultra-competitive framework in any mass vehicle sales market, both light and commercial.

Next generation of brakes with zero mobility emissions

At BRL we offer a disruptive product for the brake market adaptable to any wheel in motion.

Patented Technology

Patented Technology

Our Company

BRL is a company dedicated to research and development, specializing in the automotive sector. With highly qualified engineering, it analyzes which elements or systems require technological evolutions and innovations.

At BRL, we value our R&D&I capabilities to create new products and offer the OEM market and end customer the best technological options, which represent a leap in both performance and cost.

At BRL the essence of our values is research and customer satisfaction.

BRL has set itself the goal of evolving and innovating the current brake system, to improve it and cover its technical limitations, which represents a great research challenge.

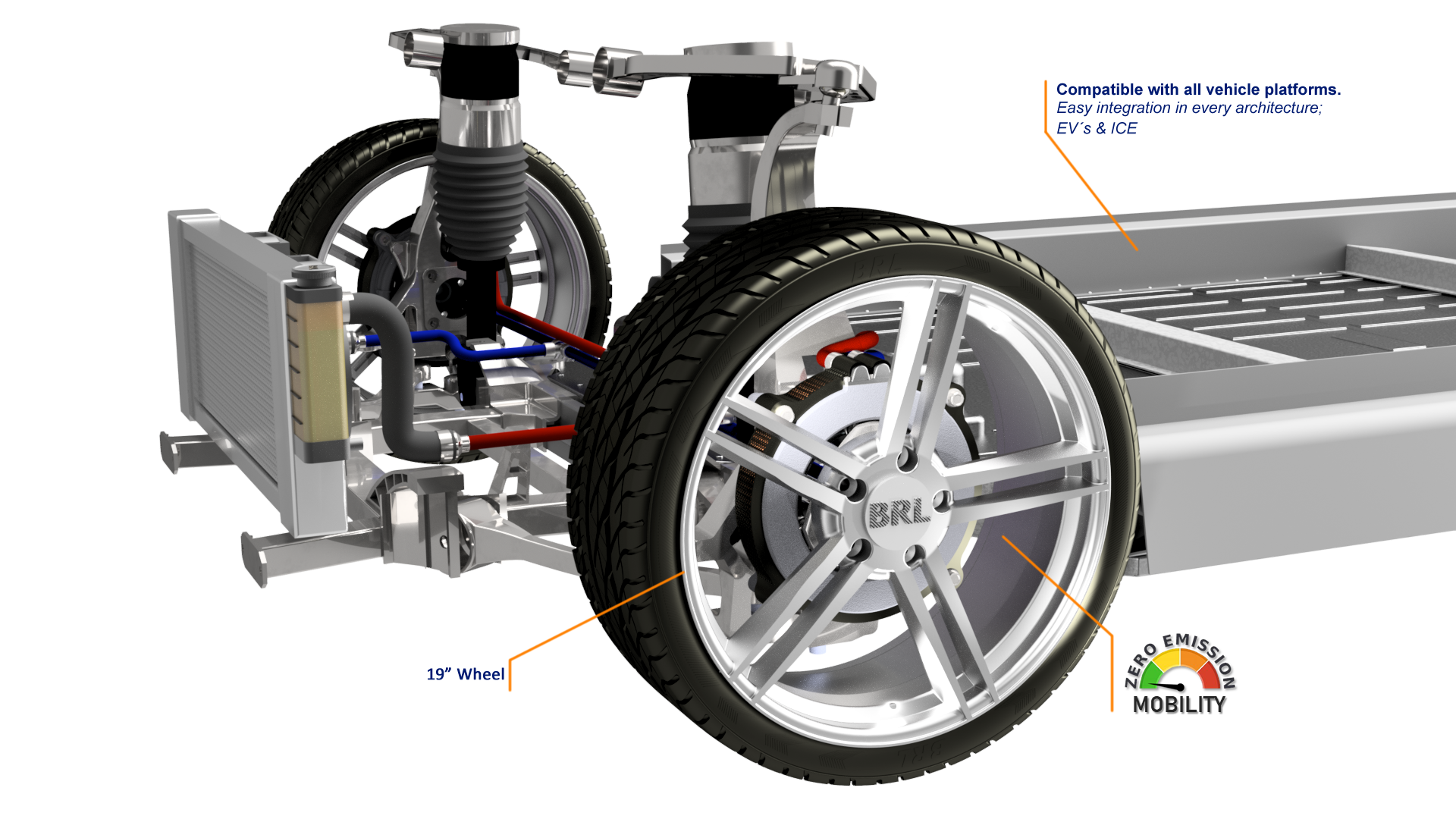

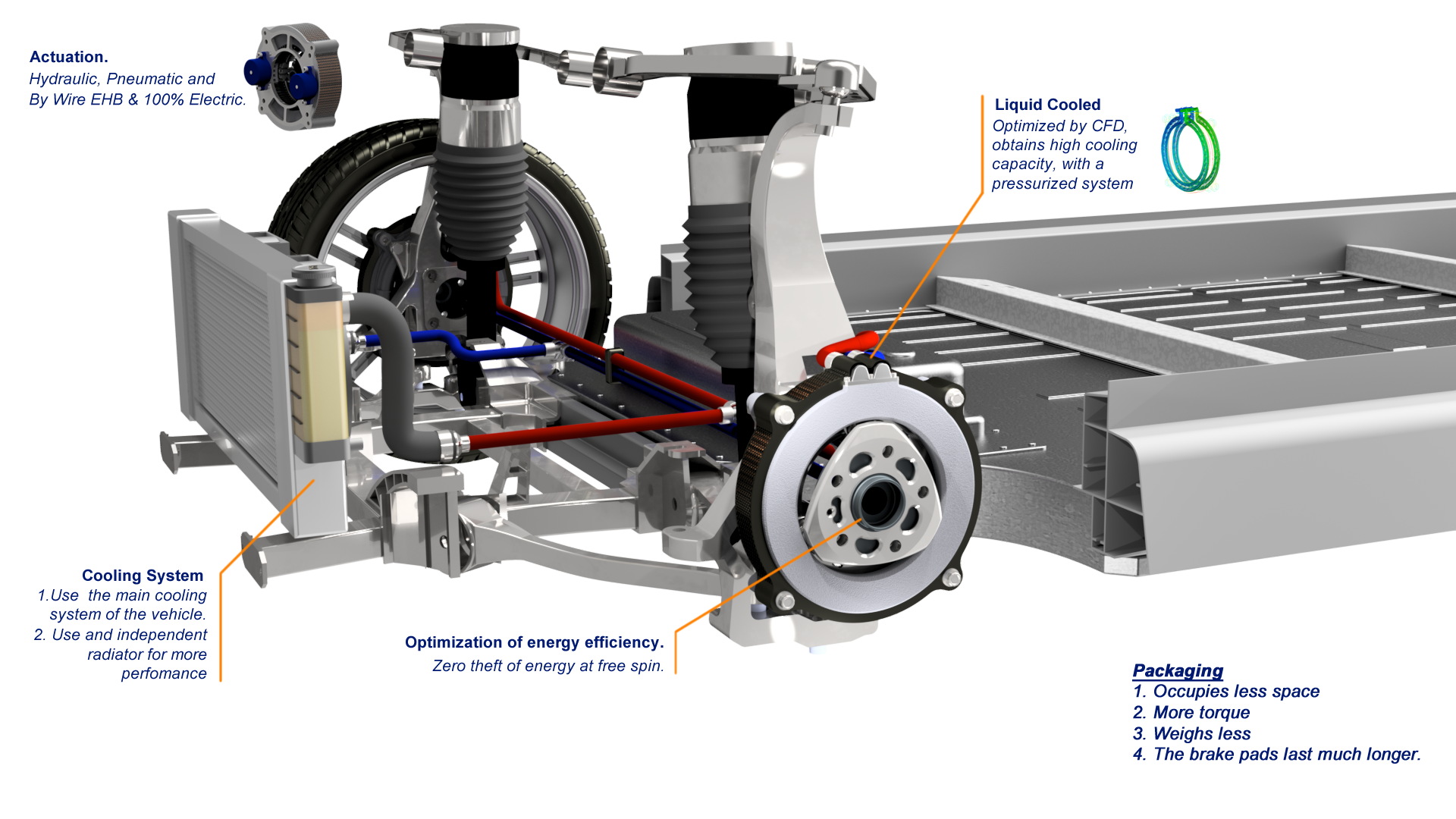

BRL, with its engineering team, has developed a completely new Brake System, which marks an important technological leap, and solves the limitations of traditional systems, clearly betting on the industrial and environmental transition, which, having a system Free of emissions, it allows, together with EV, to offer the market a more sustainable and performance mobility model.

Another objective of BRL has been to solve environmental pollution. We have a patented system that captures 100% of the brake particles, essential for its sustainability, and which must be rigorously complied with in future regulations.

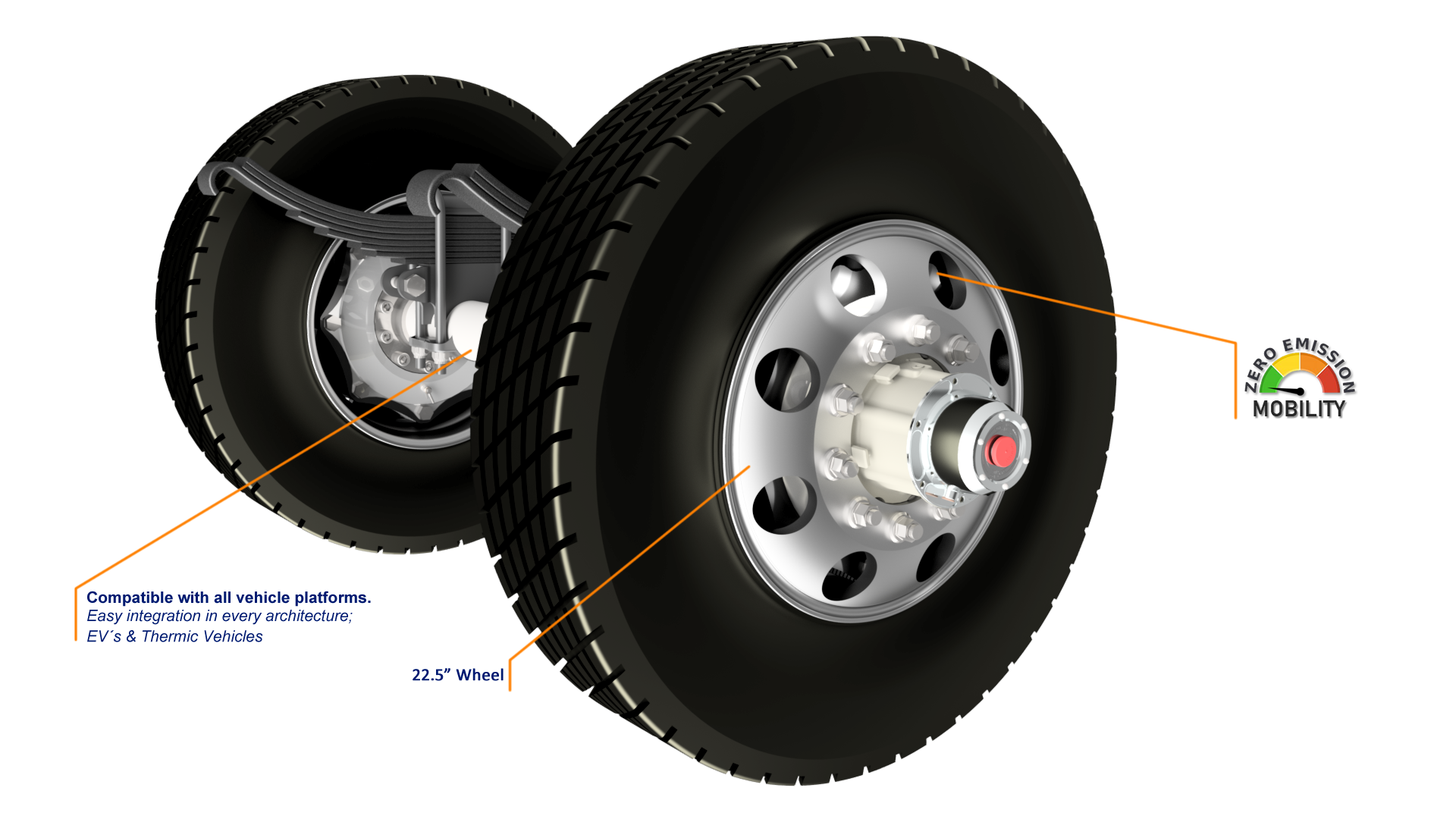

This new and very efficient «Brake Concept» is applicable to any wheel that, while in rotation, needs to be braked. It provides great advantages from a perfomance, packaging, technical, industrial and economic perspective.

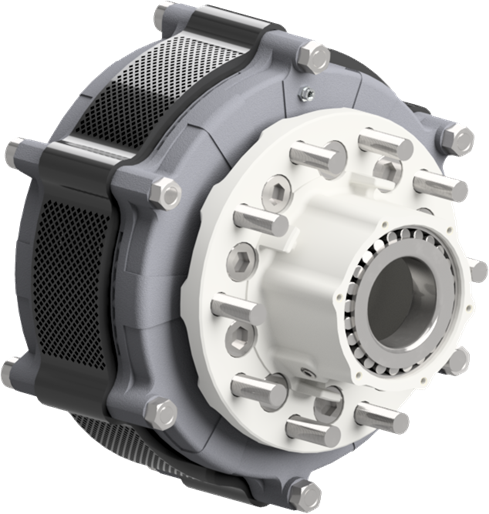

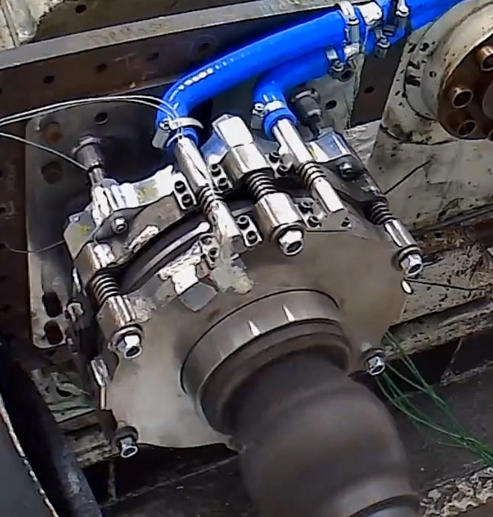

The technology has been applied to various prototypes, which have been subject to tests and certifications provided by top-tier international independent engineering firms, confirming their robustness, safety and performance.

Extraordinarily versatile and conceived to adapt to any platform, whatever its displaced energy.

Next Generation of Brakes

Product Technology

BRL offers a unique brake application with very wide product range for all types of automotive applications.

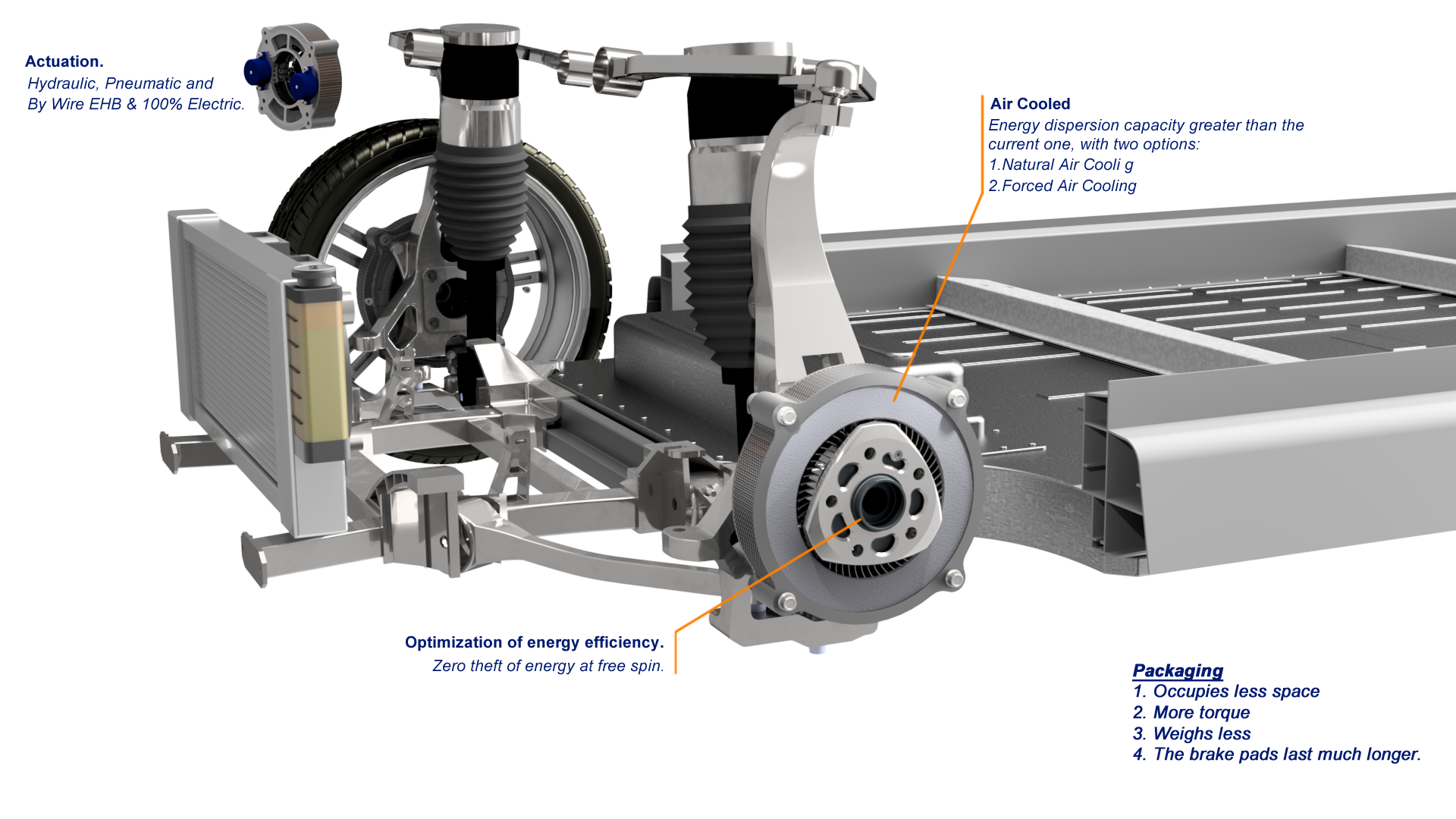

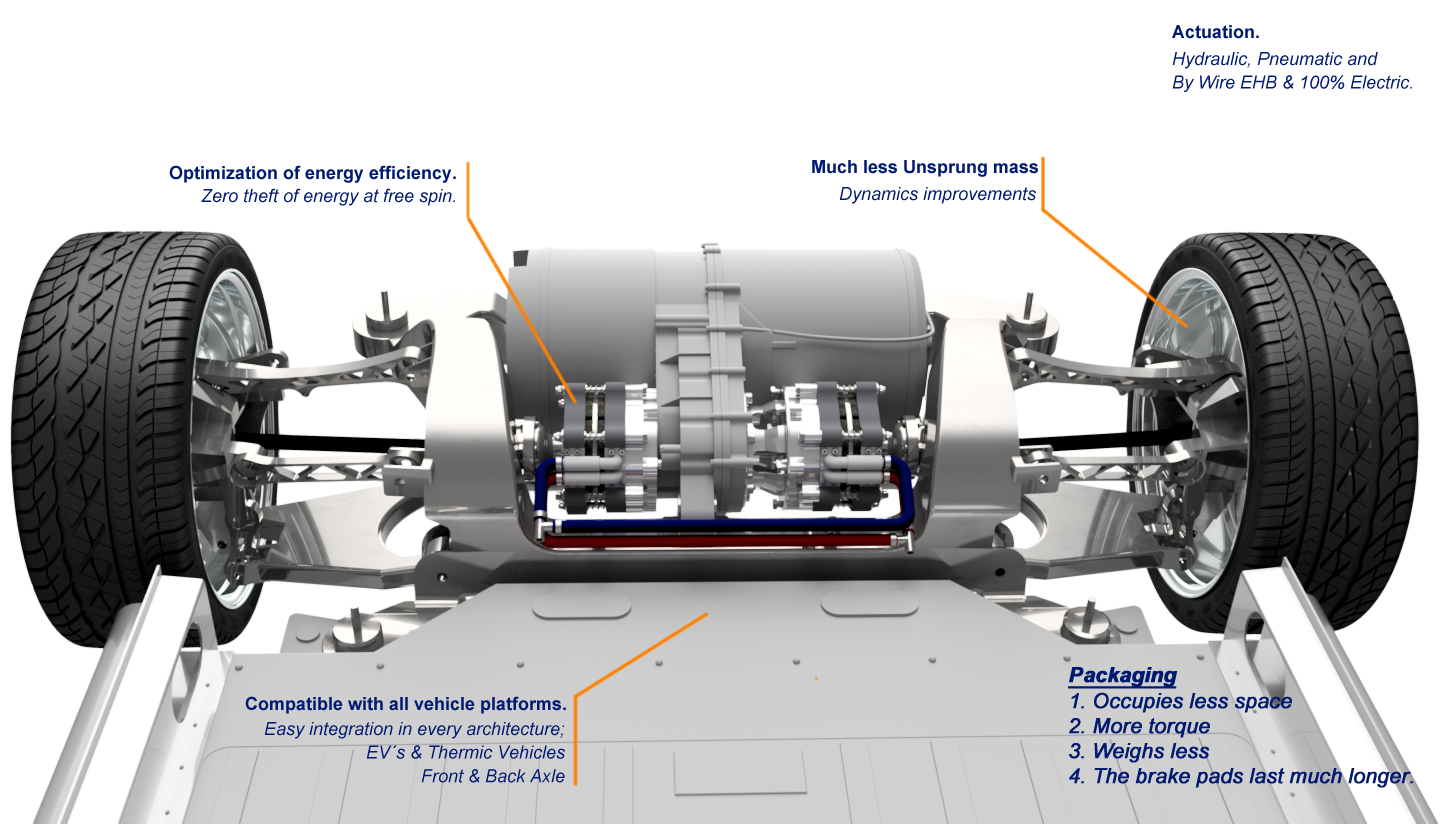

The technology of the product, thanks to its innovative and patented characteristics, is capable of adapting to any architecture available on the market, offering a leading product in the brake segment.

The engineering team has the technology, know-how and means to integrate any model of BRL brake products into a specific platform.

The great variety of permutations on the characteristics of the system supported by BRL technology, mean that any integration and implementation can be carried out from both light vehicles and commercial vehicles of any mass.

Tested

Zero Emissions Movility

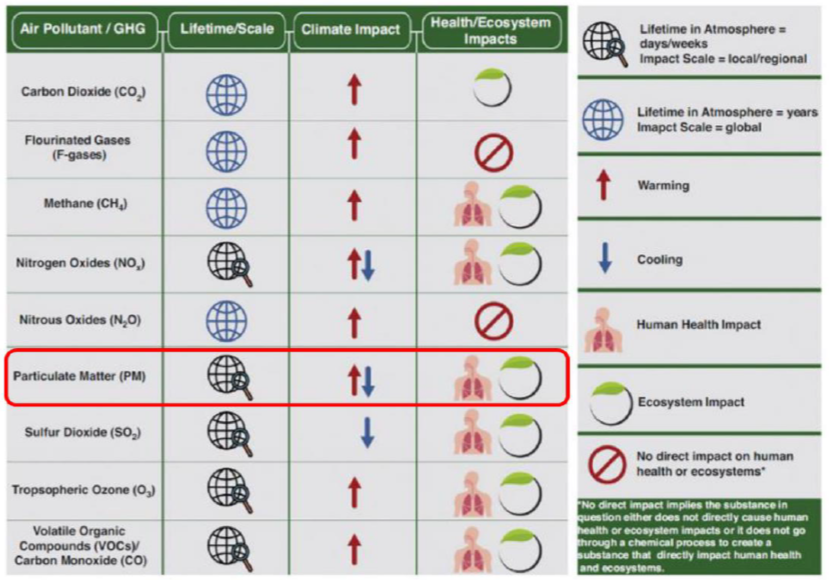

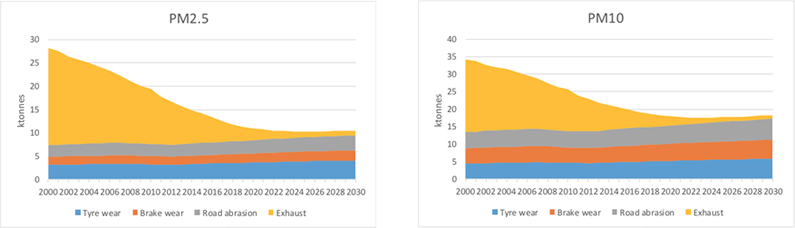

The BRL team has placed a special emphasis on the design to obtain the best advantages in the integration of EVs of any mass. We incorporate a patented and unique system for the non-emission of PM10 and PM2.5 brake pad particles into the environment, betting on environmental sustainability and the lowest impact on the environment of use.

Product Range

Perfomance & Advantages

As we mentioned in our goals, BRL is presented as the best solution on the market for the non-emission of brake particles into the environment, in terms of simplicity and costs.

Protection against external agents.

No emission of particles into the environment.

Cleaner rims.

Fulfil in excess upcoming Brake Non-Exhaust emissions regulation.

Industrial standarization, with less SKU´s of BRL models we can cover the market, both electric and combustion vehicles, as well as commercial vehicles of any mass.

BRL is assembled on-block on the production line:

Less assembly time on the production line.

Improvement costs of quality control in the assembly line.

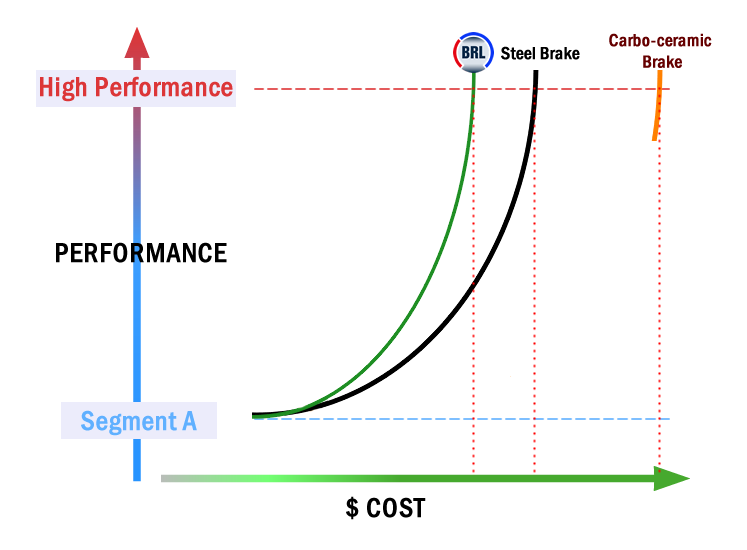

BRL is able to obtain the highest performance and the maximum duration of its components only with the use of standard materials. Therefore, depending on their specifications, our clients will obtain a system that ranges from the minimum to the maximum performance with standard market materials such as cast iron, aluminum alloy and steel.

Longer component life if desired, with great flexibility in brake pad material volume.

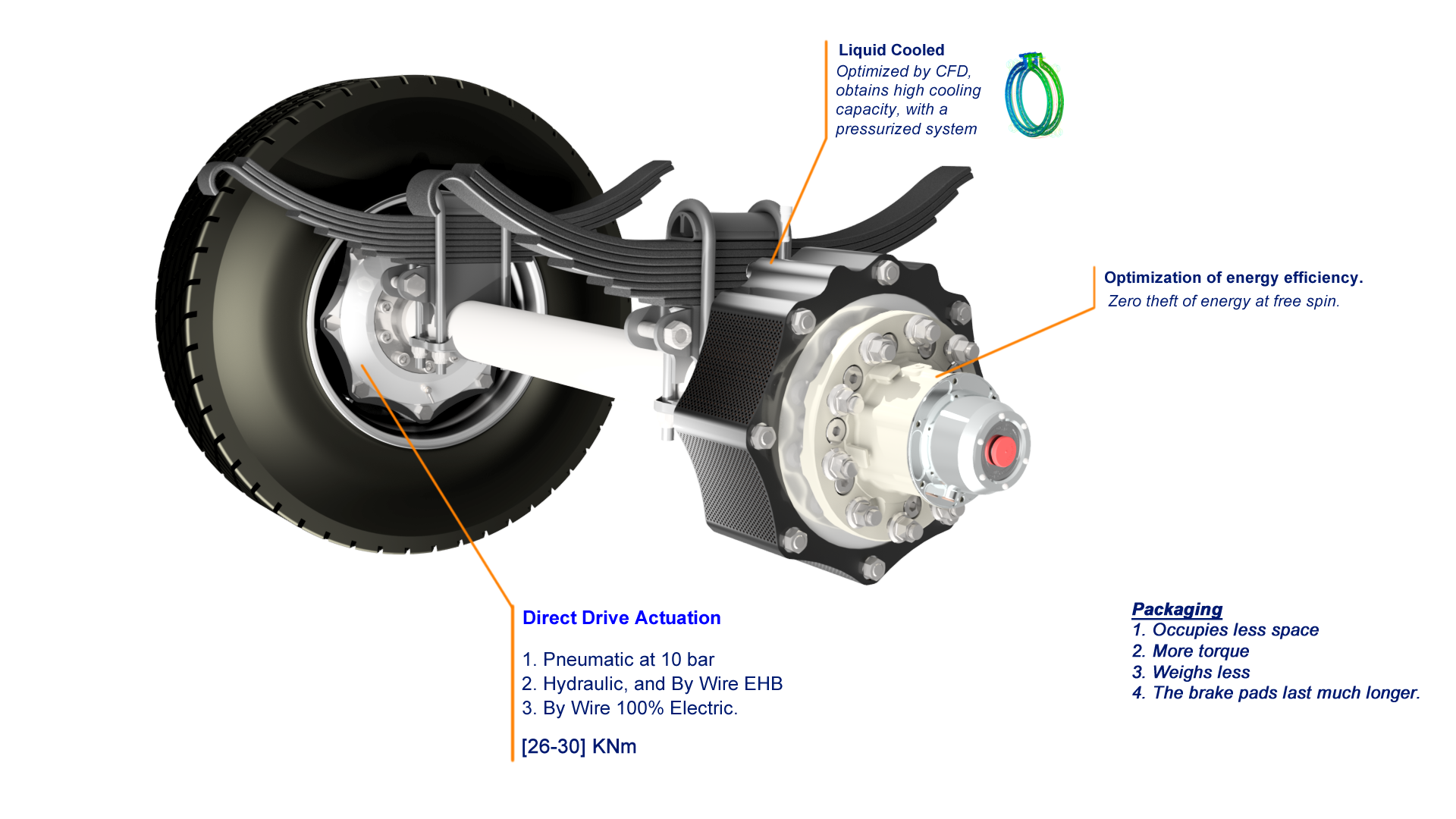

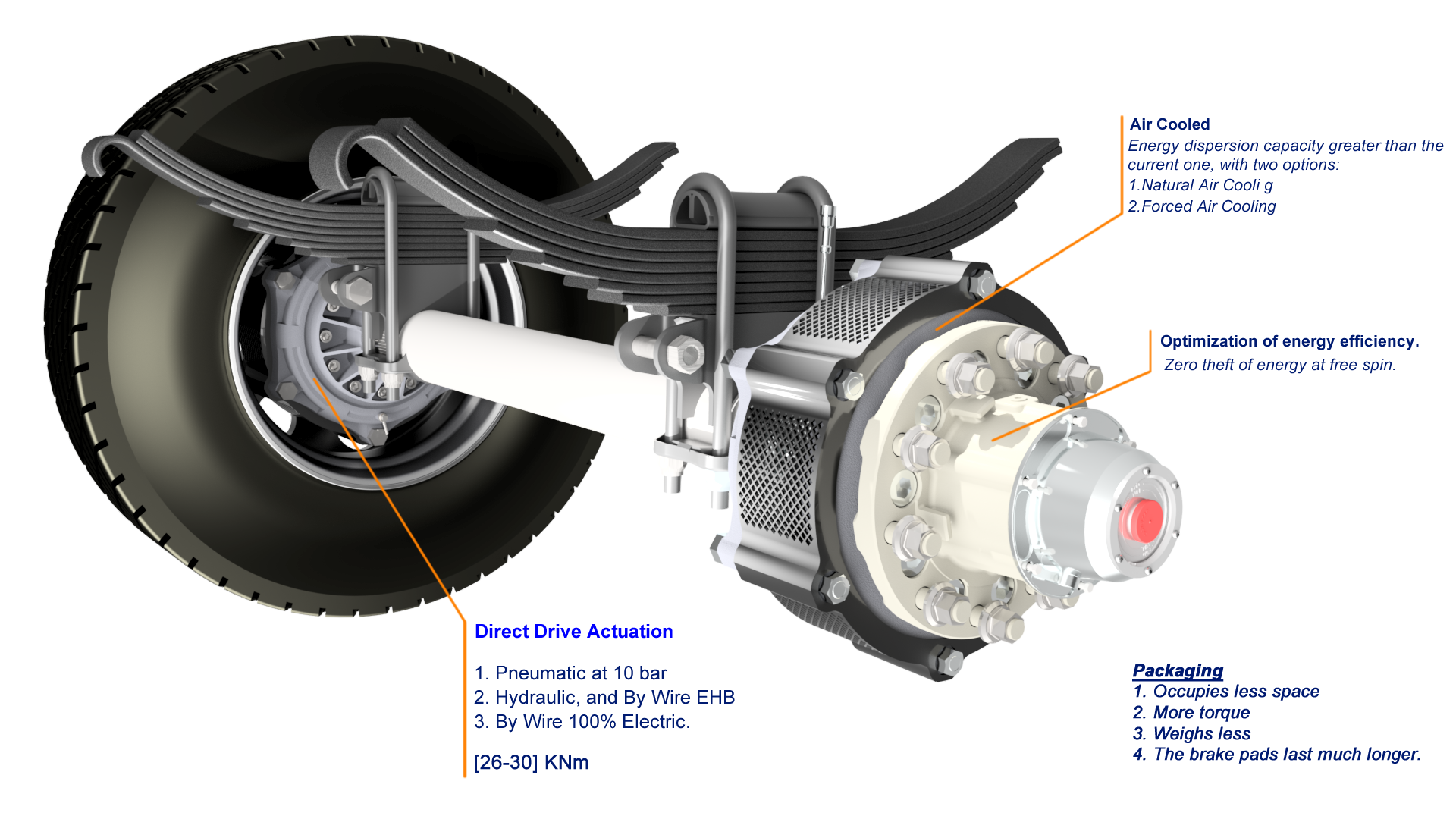

Brake actuation

Types of actuation system:

– Hydraulic and EHB (Electric hydraulic by wire).

– By Wire 100% electric.

– Pneumatic. 10 bar

Much more braking torque with a smaller packaging

Thermal

Two cooling options: liquid [LR] and air [AR].

– Lower weight.

– Ability to control the temperature at the brake.

– Longer life of the brake components.

Friction surface

BRL has, higher ratio of friction surface in every model:

– Better distribution of energy per cm2, means less wear.

– Better packaging chosing the volume and units of brake pads components.

– We can determine the appropiate stroke.

Chassis & Dinamics

– Installation as Unsprung mass, with less mass

– Can be implemented as Suspended mass, improving performance, dynamics and efficiency.

– Much lower rotating mass, means les inertia on the brake system

Mechanical & Packaging

– High flexibility and in changing system measures to achieve a specific application.

– Compatible with the current packaging of all vehicles, Stub axle and hub.

– Greater rigidity with less weight than the current system, improving pedal feel. Both with and without liquid refrigeration.

– Isolates vibrations, improving NVH tuning.

– Compatibility with electronic brake systems ABS, ESP, Torque vectoring etc. Less time to lock (TTL).

– Zero braking torque at free spin, improving energy losses.

Addressable Market

BRL is a highly scalable technology adaptable to its application to the braking systems of any category of vehicle…

…as well as it can be revolutionary in motorsport categories, where BRL technical advantages are maximized

Passanger Vehicles

Commercial Vehicles

Military Vehicles

Aviation Industry

Railway Industry

Motorsports

Applications for each category of motorsport, increasing performance and reducing costs.

Zero Emission

Zero Emissions Mobility

BRL offers a unique and patented technology in the brake emissions segment.

“BRL is the best solution on the market, in terms of cost and packaging, for PM2.5 and PM10 brake emissions”

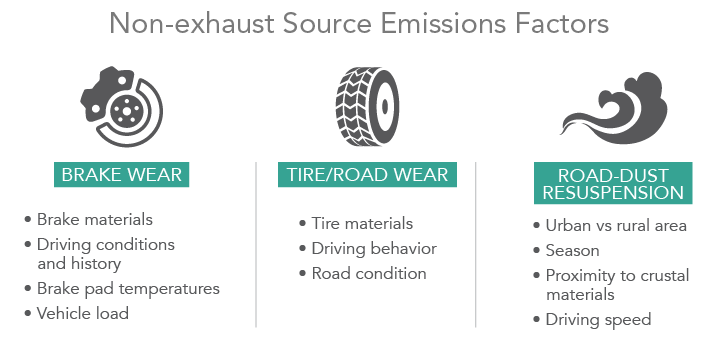

Brake Emissions News

Pollution, Effects & Regulations

What is air pollution?

Fine particulate matter (PM2.5) can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs.

Exposure to PM2.5 can cause diseases both to our cardiovascular and respiratory system, provoking, for example stroke, lung cancer and chronic obstructive pulmonary disease (COPD).

New research has also shown an association between prenatal exposure to high levels of air pollution and developmental delay at age three, as well as psychological and behavioural problems later on, including symptoms of attention deficit hyperactivity

disorder (ADHD), anxiety and depression.

For Further info:

https://www.un.org/sustainabledevelopment/blog/2018/03/who-breathe-life-how-air-pollution-impacts-your-body/

https://www.who.int/data/gho/data/themes/theme-details/GHO/air-pollution

https://www.who.int/health-topics/air-pollution#tab=tab_2

https://breathelife2030.org/news/w-h-o-air-quality-guidelines/

“Eurobrake 2021: Brake emissions regulation inmminent as non-exhaust emissions surge”

“HEI issues RFA to study non-tailpipe particle emissions”

“HEI issues RFA to study non-tailpipe particle emissions”

“Tailpipe Particulate Matter Emissions and Exposure”